Many centuries ago, it took a swift cut from the hand of a blacksmith to perfectly split an item in half, and other than this, pretty much no other way of doing that was known to men. Those who specialized in blacksmithing were strong, skilled and they surely knew their way around swords, but were they more effective than today’s lasers? We don’t think so.

As much as we are in love with the beautiful medieval period of history, we’re probably equally as glad that we have modern technology these days, and this article will serve as our appreciation post for it. Inventors around the globe spent so many years working together and coming up with new things that can make our lives easier, so the least we can do is use their technology to achieve that goal. First came the wheel, then came the first airplane, but suddenly… there were lasers.

It’s not a secret that ever since lasers came out the industry changed three hundred and sixty degrees for the better, which is why today we’re going to help you learn some more about them. Lasers are used in medicine, in the manufacturing industry and tons of different fields of life. If you want to learn how to get started with laser-cutting, this is the right place to be.

What is laser cutting?

It’s okay to be unfamiliar with this topic since not everyone is tracking the latest trends in the industries. Our job is to help you understand things better, so let’s take a look at the following definition:

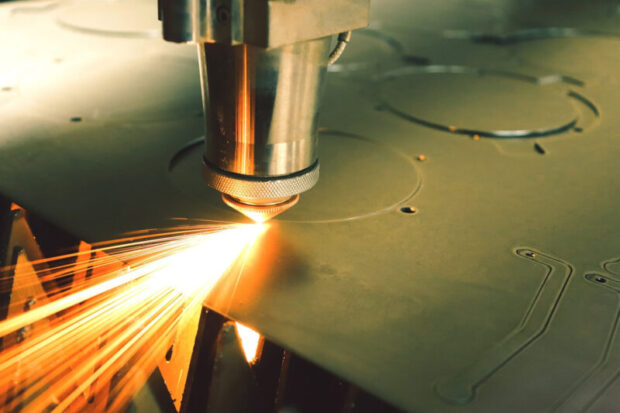

Laser Cutting is a modern technique used for precise and delicate work, performed with the help of special machines. The goal of this method is to perfectly slice a certain material in half, or in any other shape that might be required for the final product or project. The main “performer” in this process is the ultra-high powered laser that’s most commonly used through optics.

What is it useful for?

This technique is not only used in the industries, and it has a bit more “casual” use as well. Although it’s not on the same level as in large factories, schools often use this method in science classes and for other types of projects. It’s useful for many things, but the main one is effectively cutting a sturdy material without causing any collateral damage to it.

If for some reason you need something cut professionally and smoothly by a laser, but you don’t want to or cannot do it on your own, paying for a laser-cutting service is a valid option. If you’re doing this frequently however, it might not be very cost-efficient, and you might be better off purchasing the device for yourself in the long-run.

What do I need to start?

There are numerous different laser-cutters on the market, some meant strictly for professional use and some that allow casual testing, experimenting, and all that’s outside of serious manufacturing purposes. So, to simply begin with this, you’ll need to purchase a laser-cutter, and this happens to be a bit more complicated than some people think. You cannot simply go and grab the one that looks the coolest because there are different types, and each one of those types is meant for a different workflow. There are CO2 lasers and gas lasers for example. The first type is used for engraving materials such as textiles, leather, wood, paper, and even acrylic. We might not be very professional in this area, so for a better explanation and in-depth guide you can visit DxTech. Metal Laser Cutters or Metal Laser Cutting Machines are all things that you’ll need to do some research on before purchasing.

After you’ve selected which cutter you’re going to buy, it’s time to start achieving your goals. You can create decorations out of wood, metal, or any other material, as well as do engravings on custom parts and tons of different cool things. The possibilities are endless.

How is this method superior?

This method is superior to other cutting methods simply because it allows you to work on materials that are otherwise very difficult to even bend, not to mention cutting them in half. However, that’s not the only reason. As we mentioned above, with a laser cutter you can do a lot more than just cutting. Marking, engraving, and tons of other things are an option as well.

Modern laser cutters are easy to control, they pack quite a lot of power and they’re not as expensive as they were when they were first introduced to the public somewhere in the sixties. Anyone can have a cutter in their own home these days if they’re willing to invest.

Is the use of lasers legal?

You’re probably wondering if you’ll need a permit or some sort of proof that you require this type of machine to do your job, but the answer is simply no. You don’t need anything to purchase a laser cutter for your purposes, hobbies, school projects, or whatever it is that you’re doing. Lasers of this type are completely legal to use. Don’t confuse these with pointing lasers which can sometimes be illegal to carry in certain situations.

What else do I need to know?

Our safety and the safety of our readers is our number one priority, which is why we decided to add this list at the end of our article with all the materials that you shouldn’t try to cut or engrave with a laser cutter. Let’s take a look.

- Beryllium Oxide

- Epoxy

- Carbon Fiber

- Leather

- Polyvinyl Chloride

- Polyvinyl Butyrate

If you want to create a design and use that same design for some computer-controlled laser-cutting, you should do it in the form of a vector image. For those of you unfamiliar with this, a vector image stores the shapes and color-choices of your file in the form of a mathematical formula. This allows the computer to know exactly what you were planning to do and what you’re expecting to come out as the final result.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024